Produkcja form dla przetwórstwa tworzyw termoplastycznych oraz kompozytów

Nasza spółka Linaset łączy w sobie z jednej strony ponad pięćdziesięcioletnią tradycję produkcyjną, a z drugiej strony najnowocześniejsze wyposażenie maszynowe oraz oprogramowanie konstrukcyjne. Dotyczy to produkcji form wtryskowych oraz form bezpośredniego tłoczenia dla obróbki tworzyw termoplastycznych, kompozytów, materiału BMC oraz SMC. Największym przemysłowym firmom świata zapewniamy kompleksowy serwis od rozwoju, poprzez konstrukcję aż do produkcji form najróżniejszych typów. Formy wtryskowe możemy produkować aż do ciężaru 10.000 kg. Formy jednak nie tylko produkujemy, ale przy ich pomocy sami produkujemy wytłoczki. W naszych zakładach wykonujemy również montaż poszczególnych części aż do stanu produktów finalnych.

W powiązaniu z produkcją form świadczymy kompleksowe usługi od projektu 3D do serwisu oraz testowania

Do produkcji form w celu przetwarzania tworzyw termoplastycznych oraz kompozytów mamy do dyspozycji cały szereg doskonałych narzędzi programowych oraz najwyższej klasy maszyny. Poszczególne projekty przechodzą z reguły przez następujące fazy.

Przekazanie dokumentów

Dane do projektowania służące do opracowania oferty przyjmujemy w każdej z następujących form: serwis klienta i e–mail. Formaty modeli 3D przyjmujemy w następujących formatach: STEP, IGES,CATIA v5. Formaty aplikacji danych 2D przyjmujemy w formatach: DWG, DXF, CATIA v5.

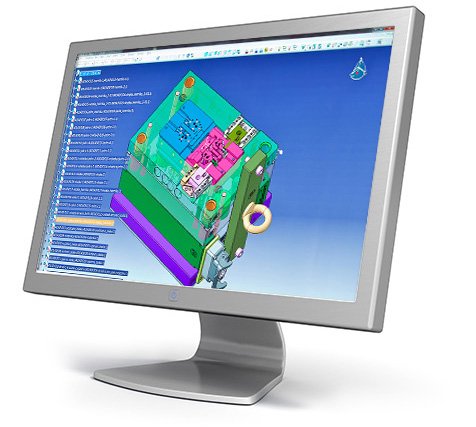

Projektowanie i kontrukcja form

Na podstawie dostarczonych materiałów stworzymy 3D projekt zespołu formy, przeprowadzimy FMEA analizę konstrukcji formy. System dopływowy, proces formowania wtryskowego i deformacji wytłoku optymalizujemy za pomocą analiz oprogramowania CADMOULD 3D-F Analiza Mouldflow za pomocą oprogramowania Cadmould 3D–F umożliwia przeprowadzenie symulacji formowania wtryskowego, dzięki której możemy wykryć potencjalne błędy już podczas konstrukcji części plastikowych lub narzędzia do prasowania tworzyw, w ten sposób zaoszczędzić koszty i czas. Analiza Moldflow określi optymalną pozycję i liczbę wpustów, albo odkryje miejsca, w których powietrze zostanie zamknięte lub będą zimne łącza. Cadmould 3D–F jest również w stanie obliczyć okres realizacji, temperaturę głowicy stopu, rozdzielenie ciśnienia we wnęce matrycy podczas napełniania, problemy z napełnianiem, czas odkształcenia, kurczenia i deformacji, temperaturę chłodziwa w obwodzie chłodzenia itd.? . Do przetwarzania dostarczonych rysunków używamy przede wszystkim najwyższej jakości 3D CAD systemu Catia v5 , a następnie programów Rhinoceros 4.0, Autocad 2006 LT, CadMould 5.0 oraz ENOVIA DMU 5.2.

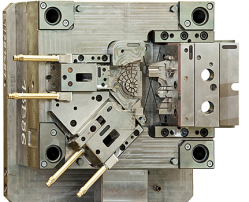

Właściwa produkcja form

W narzędziowni naszej firmy Linaset potrafimy wyprodukować formy wtryskowe oraz formy bezpośredniego tłoczenia od prototypów do form dla produkcji seryjnej. Formy w końcowym etapie testujemy a następnie przekazujemy do produkcji seryjnej części. Na etapie rozwoju oraz produkcji form stosujemy najwyższego poziomu sprzęt pomiarowy. Poniżej podajemy zestawienie typów form produkowanych w spółce Linaset:

- formy prototypowe oraz formy dla produkcji seryjnej

- formy dla skomplikowanych pod względem technicznym części

- formy dla wtryskiwania 2K

- formy dla części z zapraskami

- formy dla części estetycznych

- formy dla części kompozytowych

Serwis form wtryskowych oraz form bezpośredniego tłoczenia

W ramach usług serwisowych świadczymy wyspecjalizowany serwis form na cały okres żywotności narzędzi, w zakresie napraw form, wykonujemy różne prace o charakterze przemysłowym, wykonujemy testy form lub naspawanie laserowe.

Maszyny, wyposażenie technologiczne oraz elementy standardowe (normalia) stosowane do produkcji form

Dla produkcji form dysponujemy najnowocześniejszym wyposażeniem maszynowym od firm Exeron, Roeders, Trimill albo Wenzel. Proces sterowania projektami oraz produkcji wspieramy systemami Zwicker. Stosujemy wyposażenie standardowe (normalie) w szczególności od firm Hasco, DME, Meusburger, Strack oraz gorące systemy firm Mold Master, Synventive oraz Incoe.

Realizowane projekty oraz referencje

Formy wtryskowe oraz formy bezpośredniego tłoczenia spółki Linaset stosowane są do produkcji wytłoczeń technicznych głównie w przemyśle samochodowym oraz elektrotechnicznym. Typowymi produktami finalnymi są przykładowo układy hamulcowe, układy pedałowe oraz układy wycieraczek, technika świetlna do samochodów, klimatyzacja, części wnętrz samochodów, styczniki, wyłączniki samoczynne, listwy zaciskowe, boksy oraz puszki elektryczne, elementy rozdzielcze oraz różnego rodzaju odbiorniki domowe. Do naszych największych klientów zaliczamy przykładowo spółki ABB, Bosch, Braun, DeLonghi, Hella, Mahle Behr, Marelli Automotive Lighting, P&G, Siemens, UFI Filters, Varroc Lighting Systems, ZKW, itp.

Informacja na temat świadczonych usług

-

Produkcja form wtryskowych oraz form bezpośredniego tłoczenia

-

Serwis i naprawy form

-

Sporządzanie dokumentacji rysunkowej

-

Opracowanie analizy Mouldflow

-

Testy form

-

Kooperacja w produkcji maszynowej

-

Pomiar 3D przy pomocy przyrządów pomiarowych Wenzel LH 87

-

Digitalizacja elementów do modeli 3D

-

Opracowywanie programów dla pomiarów 3D

-

Pomiar przy użyciu urządzeń optycznych 2D Excel 501 HM

-

Pomiar chropowatości Rz, Ra

-

Dalsze pomiary przy użyciu standardowych mierników komunalnych

-

Raporty wyjściowe w postaci protokołu pomiarów, modelu 3D, ewentualnie innego formatu odpowiednio do porozumienia z zamawiającym

-

Protokoły pomiarowe wg norm VDA, PPAP.

-

Pomoc fachowa przy opracowywaniu metodyki pomiarów, wyborze najkorzystniejszego sposobu pomiarów

Kluczowe zalety konkurencyjne

- Silna i duża spółka posiadająca stabilną pozycję na rynku oraz doskonałą sytuację finansową. Dwa zakłady produkcyjne.

- Kompleksowa oferta usług od projektu części, poprzez produkcję narzędzia, dostawy wytłoczek aż do montażu.

- Wykwalifikowany i doświadczony personel wspierany przemyślanym systemem podnoszenia kwalifikacji.

- Najwyższej klasy urządzenia produkcyjne czołowych światowych producentów pras Arburg, Engel, KraussMaffai lub Lauffer.

- Zastosowanie nowoczesnych technologii, takich jak przykładowo metoda wtryskiwania 2K.

- Przemyślany system jakości udokumentowany przez certyfikatyEN ISO 9001, IATF 16949, EN ISO 14001, EN ISO 45001, EN ISO 27001:2022 oraz EN ISO 50001

- Zarządzanie produkcją oraz procesami w oparciu o metody produkcyjne TPM, SMED i dalsze.

- Bardzo duża elastyczność zapewniona dzięki możliwościom produkcyjnym oraz doskonałemu systemu zarządzania produkcją i logistyki.